![]()

Based in the USA and India, the DESCO Group is now offering consultation and engineered solutions to provide a global market with the neccessary engineering services such as, but not limited to:

• 2D Drafting & Detail Engineering

• PDMS, Piping Engineering & 3D Modeling

• Design and Engineering

• FEA & Stress Analysis

• Cargo Carrying Unit (CCU) Designing

• CFD Solutions

• Civil and Architectural Design Solutions

• Value Engineering and Other Services

![]()

![]()

![]()

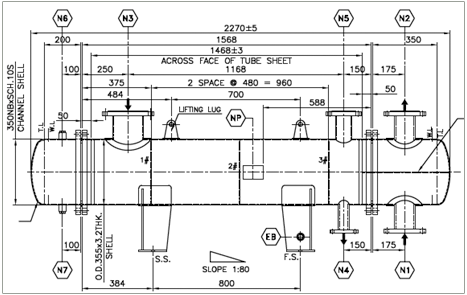

• GA drawings of process equipment

(Boilers, Heat Exchangers, Pressure Vessels, etc.)

• API-650 Storage Tank drawings

• Structural drawings(beam structure, foundation and floor plans, etc.)

• Pressure part drawings & detailed drawings

• Fabrication drawings

• Parts and development drawings

• Weld-map drawings

• Ducting drawings

• Isometric piping drawing

![]()

![]()

![]()

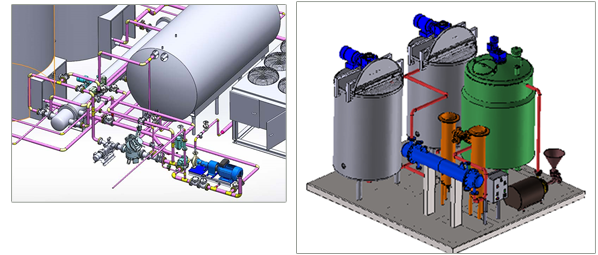

• 3D modeling of piping & plant layout in PDMS

• Plant and piping layouts, P&IDs

• Isometric piping drawings with supports

• 3D modeling of process equipment

• Conceptual drawings & models

• Models for stress analysis

• Skid mountings

• Pump Skids

![]()

![]()

![]()

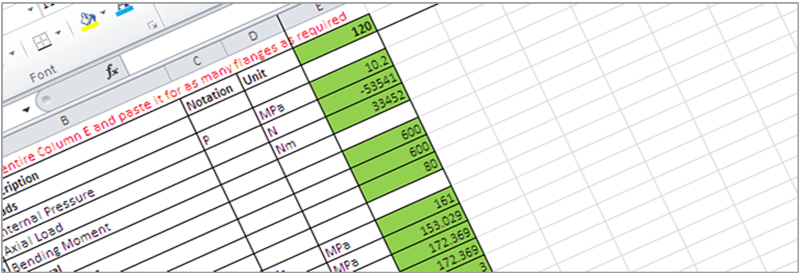

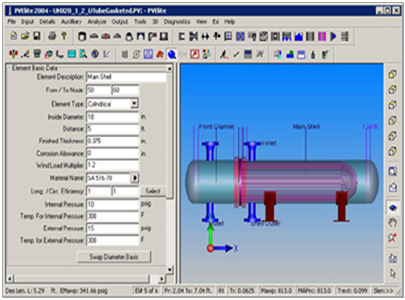

• ASME design calculations for boilers, pressure vessels & piping

• Mechanical design calculations for heat exchangers

• Designs per PV-Elite, Compress, ANSYS & CAESAR-II tools

• Nozzle load calculations as per WRC code & FEA

• Designs calculation for ASME, IBR, TEMA, PED, BS, EN & PD-5500

• Documentation for ‘U’ stamping / ‘ASME’ marking, ‘CE’ marking

• Documentation for ‘R’ stamp (repair work)/ ‘L’ mark (lethal duty)

• Documentation for DOSH, GOST, SELO – ML certifications

• Storage tanks designs according to API -620 and API-650

• ASME weld qualification documents (WPS, WPQ and PQR)

• Design and drawing appraisal from TPI

• Static analysis of vessels for wind and seismic loads

![]()

![]()

![]()

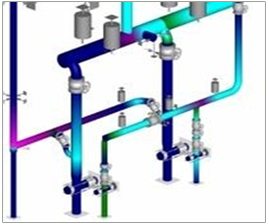

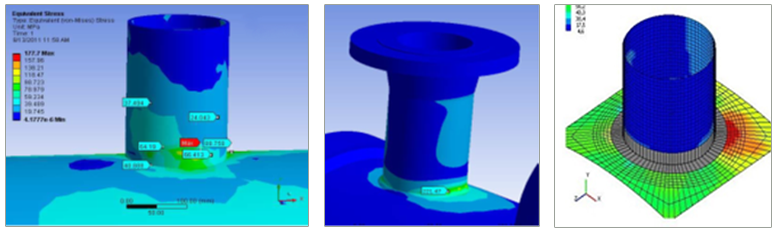

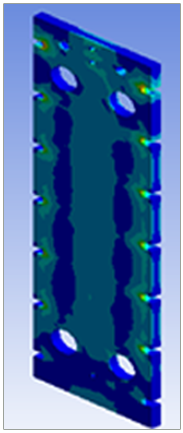

• Stress analysis of pressure equipment

• FEA (Finite Element Analysis) of pressure and non-pressure parts

• Thermo-Structural analysis of piping and equipment

• Support analysis for wind and seismic forces

• Nozzle load and localized stress analysis

• Piping stress due to thermal expansion and support selection

• Supportive calculations per ASME Section VIII Div. 2

• Fatigue analysis

![]()

![]()

![]()

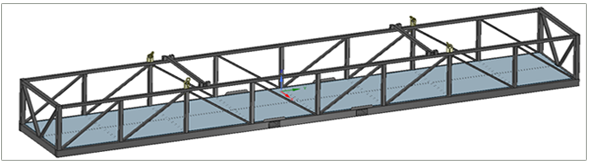

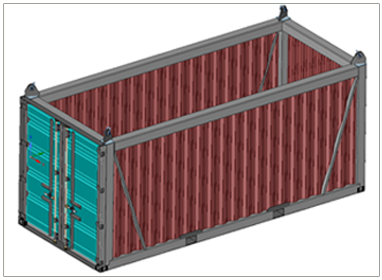

• Design Code- EN 12079

• Class Approval from DNV / BV / TUV

• Lifting Equipment Designs

• Sling and Shackle Designs

• Cargo Container Designs

![]()

![]()

![]()

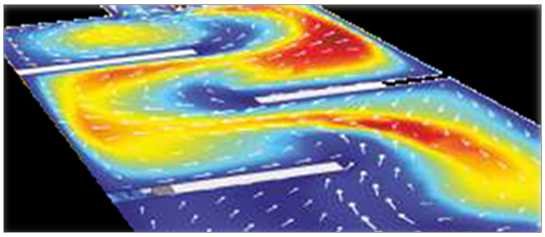

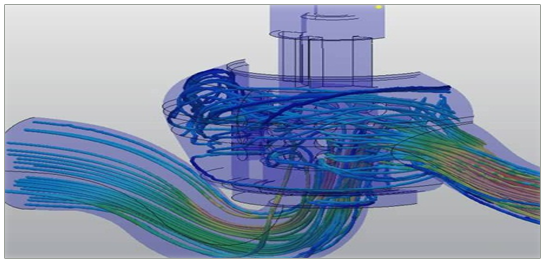

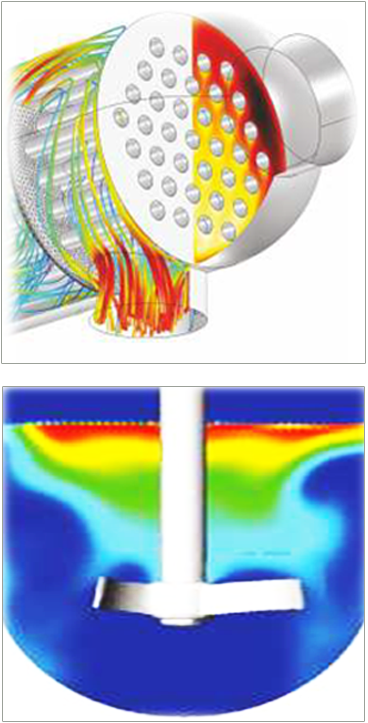

• Validation of conceptual thought and processes in industry

• Performance and rating of heat exchangers

• Analysis for irregular process solutions

• Solutions for R&D activities in product development (avoiding actual cost impact)

• Solutions for product geometric changes

• Thermal & physical behavior of fluid flow passages in operation

• Temperature & velocity profile inside flow passages

• Pressure drop analysis for various fluids

• Pump performance & validation

![]()

![]()

![]()

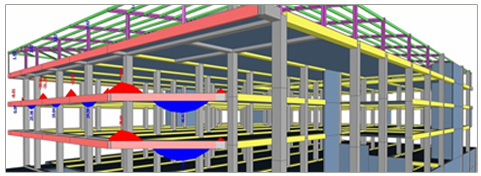

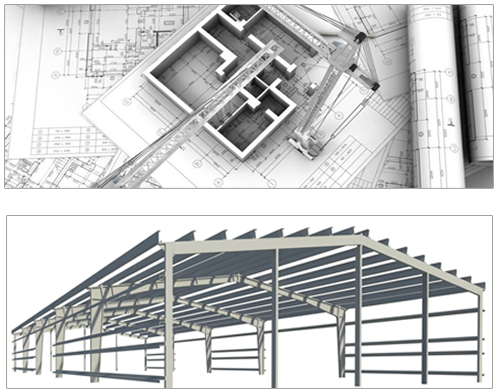

• Structural analysis in STAAD.Pro

• 3D modeling of buildings

• BIM in REVIT, TEKLA & PEB

• Architectural designs & modeling

• Layouts and plans, foundation drawings & loading charts

• Structural stability analysis

• Design & detail drafting of structural elements

• Platforms and ladders for manufacturing plant setup

![]()

![]()

![]()

• Reverse engineering

• Process validation

• Standardization of designs and products

• Design error analysis and design time reduction

• 3D printing, product animations and demo models

• Digitalization of drawings

• 2D to 3D drawing conversions

• Marketing tools on product applications

• Prototyping

• Quality certifications and audits

• Translation of Technical Documents (e.g. English to Russian)